Tue November 12, 2019

Perkins

Perkins offers a comprehensive range of overhaul solutions for agricultural engines, all of which are designed to deliver maximum performance from the engine and machine and reduce the risk of disruptive downtime.

For farmers, having a machine out of service can mean lost productivity, revenue and profits. Farmers need to know their equipment is powered by an engine that can be trusted — and that support is in place to keep it operating reliably, whatever its age or condition.

Perkins engines have a long-standing reputation for delivering the high performance, durability and longevity that farmers need but after many years of trusted service, they might show some signs of deterioration, such as slow starting in cold weather, excessive oil consumption or lack of power. When this happens, customers have easy access to a broad range of overhaul options to return their engines running to optimum performance.

Overhauling an engine involves replacing key components, while retaining core elements such as the main engine block. The benefits are significant, as it allows farmers to substantially extend the working life of the engine, increase the return on investment, and minimize the potential for downtime.

"No single option fits all situations when it comes to overhaul," Perkins aftermarket general manager Matt O'Sullivan said. "A brand-new drop-in replacement engine might be right for contractors' machines with a high capital value and where uptime is at a premium. Other applications that are used less frequently might be better served by an engine rebuild, upgrade with remanufactured parts, or repair with a genuine overhaul kit. The local Perkins distributor is best placed to help determine the best option."

Perkins aftermarket product manager Ian Bradford said, "Using genuine parts allows the engine to be returned to its original performance— or better — after an overhaul. Customers will be putting parts in the engine that have been fitted to tens of thousands of Perkins engines. This maintains confidence in the engine and machine, maximizes its life, and continues to reduce the customer's running costs long into the future."

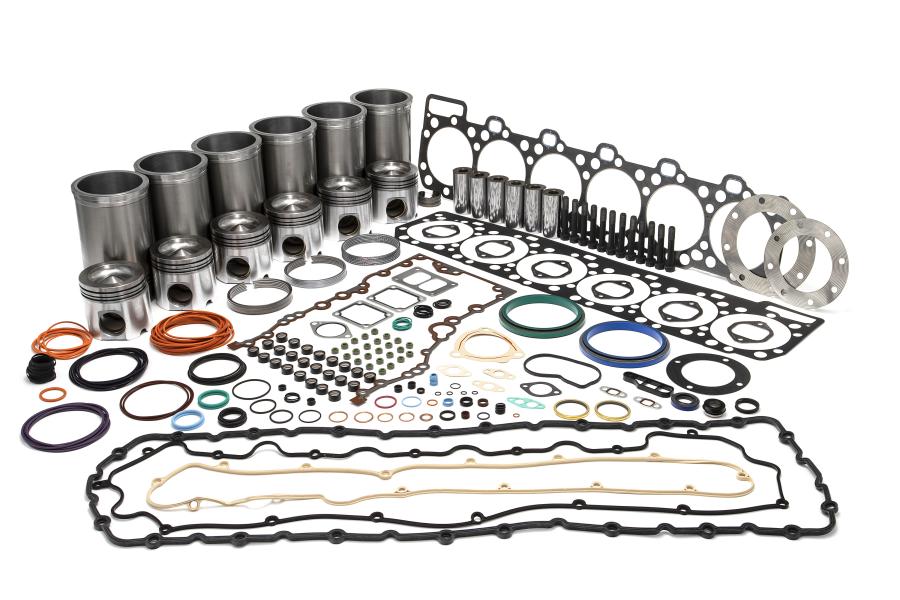

Perkins offers a wide range of overhaul options including:

- Individual parts and kits. An engine being overhauled for the first time can often be returned to full performance with a partial overhaul using standard-sized parts such as pistons, piston rings and bearings. This can frequently be done without removing the engine from the equipment, which means less downtime and cost. Choosing a Perkins parts kit rather than individual parts can also be more cost-effective. The kit will contain all the parts needed for the job — giving the customer peace of mind that the overhaul will be done properly, first time. Parts kits also are available for overhauls where the engine blocks need to be re-bored and honed. They include all the relevant oversized or undersized parts. Perkins provides parts kits for pistons and rings, gaskets and seals, engine bearings, and valves and seats. Every part is covered by Perkins 12 month warranty.

- Overhaul kits. For engines in need of more extensive care, Perkins provides kits for a comprehensive overhaul. These include complete overhaul kits, valvetrain kits for top-end overhauls, main and con rod bearing kits, and gasket and seal kits. All are available with either standard or oversized/undersized parts as required. Choosing an overhaul kit simplifies the ordering process, as customers receive all the necessary parts under one or two parts numbers. The price also will be lower than ordering individual components.

- Replacement engines. If a customer's business profitability hinges on bringing equipment back into operation as quickly as possible, they can choose to drop in a brand-new engine in place of the declining one. Perkins offer complete engines, rated long engines, long blocks and short blocks. With lead times as short as 48 hours, the machine will be up and running again in no time. And customers are guaranteed new engine performance at a fraction of the cost of a new machine.

- Remanufactured engines, assemblies and parts. Where time and cost are important factors, a remanufactured engine, part or assembly can be the best choice. The remanufacturing process starts when the customer returns the original part. This undergoes various high-tech processes to return it to the original factory specification. Perkins supports the performance of each remanufactured part with the same 12 month warranty as new parts.

For more information about Perkins overhaul options, visit www.perkins.com/overhaul.

Agricultural Equipment

Agricultural Equipment Articles

Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines

Agricultural Equipment

Agricultural Equipment Agricultural Dealers

Agricultural Dealers Agricultural Articles

Agricultural Articles Sign up for Updates

Sign up for Updates Sell Your Machines

Sell Your Machines